Industrial Fencingin Mississauga: Secure, Durable, Custom Solutions

Industrial fencing protects property perimeters by combining heavy-duty materials, engineered footings, and integrated access control to limit unauthorized entry and safeguard assets. This guide walks through common industrial fence types, how different materials hold up in Ontario’s climate, the role of gates and access control, and when temporary fencing makes sense. You’ll find practical specification advice—height, wire gauge, topping options—plus an installation and maintenance workflow to streamline procurement and compliance. We also match security features to typical risk profiles for factories, warehouses, utilities, and institutional sites, and include checklists to prepare for a vendor consultation. Finally, learn how a local Mississauga provider can tailor solutions and what information speeds up a customized quote.

Why industrial fencing matters for business security and compliance

Industrial fencing creates a clear, physical boundary that deters intrusion, controls access, and helps organizations meet safety and regulatory obligations. By delaying or preventing unauthorized entry, a well-specified fence reduces theft, vandalism, and on-site safety incidents—cutting liability and operational disruption. On sites that handle hazardous materials or heavy equipment, fencing clarifies exclusion zones and supports emergency response through controlled gates and signage. Understanding these functions helps stakeholders choose systems that match their risk profile and compliance needs before evaluating fence types and integrations.

Industrial fencing delivers three practical operational benefits that justify the investment for most industrial sites:

- Reduced theft and vandalism: A visible, robust barrier increases detection time and deters opportunistic crime

- Clear safety and regulatory separation: Fences define hazardous areas and support site safety plans and inspections

- Controlled site access: Integrated gates and readers simplify deliveries, shift changes, and contractor management

Those benefits drive choices around materials and features. The next section reviews common industrial fence types and how they perform in Ontario conditions.

How industrial fencing protects assets and supports compliance

Fencing protects assets through a mix of deterrence and engineered delay: taller, stronger fences slow intruders while integrated detection and controlled gates reduce false entries and improve response. This approach lowers loss and creates unambiguous boundaries for responders, contractors and staff—important for sites that require restricted zones. For example, a distribution centre will separate loading docks from public areas, while a utility yard uses anti-climb systems to secure sensitive equipment. Practical checklist items include correct fence height, secure footings, clear signage and controlled egress routes that support both security and inspections.

Compliance needs inform specification choices; the following subsection outlines the security features that add measurable protection for higher-risk sites.

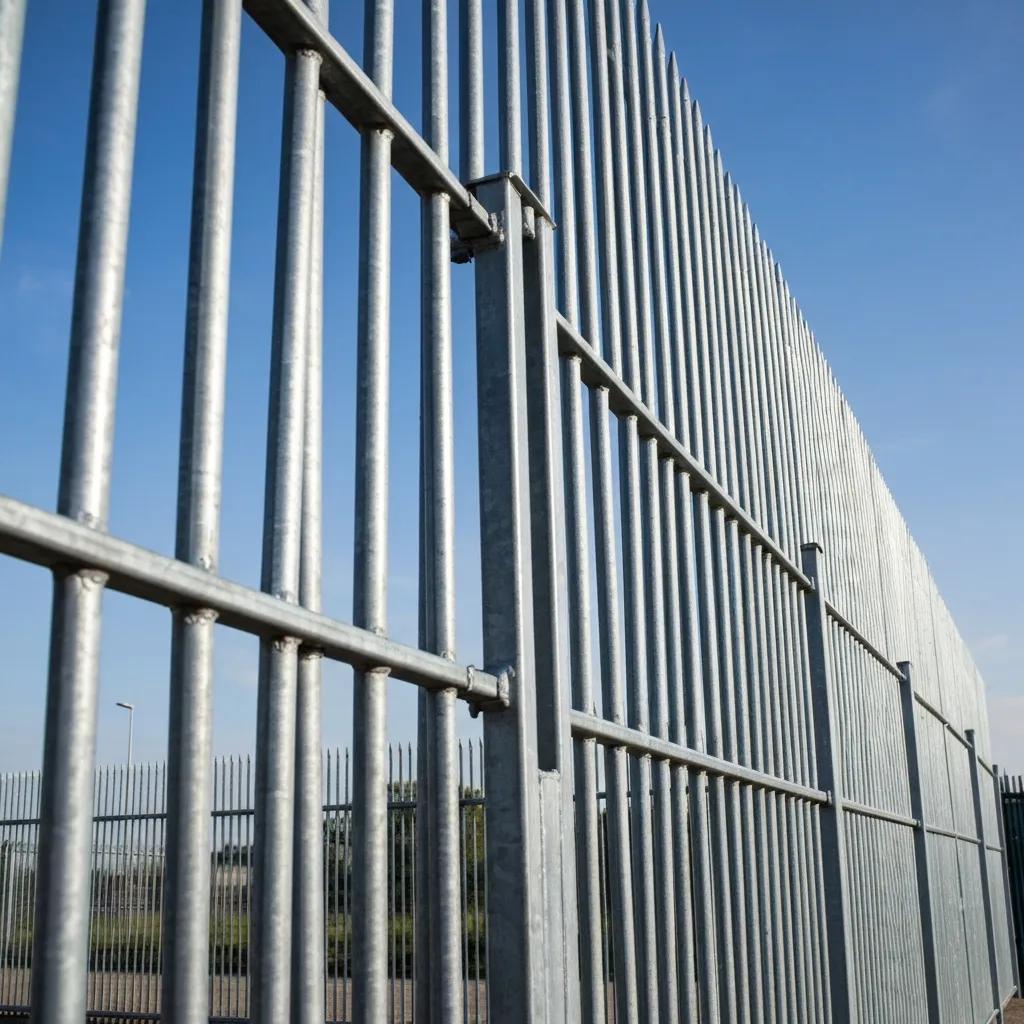

Key security features of high-security industrial fences

High-security industrial fences combine material strength, anti-climb geometry, and hostile-environment toppings to build delay and detection layers. Typical features include welded mesh with narrow apertures, steel palisade for high-impact resistance, anti-cut chain link upgrades and permitted topping options (barbed or razor-style wire). Each feature raises cost but improves resistance to intrusion. Correct anchoring—reinforced footings and adequate embedment—prevents undermining, and compatibility with CCTV and intrusion detection supports layered monitoring. Choose features based on site risk: a low-risk storage yard may need coated welded mesh, while utilities or high-value facilities often require palisade or anti-climb welded systems.

Those feature choices lead into a materials comparison to help decision-makers weigh durability, cost and maintenance trade-offs.

Industrial fencing options offered by Fencer 3000 Inc.

Industrial fencing spans temporary panels to heavy-duty palisade—each type tailored to a specific security need and lifecycle. Common options include industrial-grade chain link (with security upgrades), welded wire mesh, steel palisade, ornamental/architectural steel and temporary panels for short-term containment. Each balances security, visibility, cost and maintenance. Picking the right option means matching the fence to site activity, exposure to salt and freeze-thaw cycles, and available maintenance capacity. Below are the main categories with a quick benefit line to help narrow choices.

- Chain link (industrial grade): Affordable and flexible, with upgrade paths for added security

- Welded wire mesh: Strong anti-cut and anti-climb performance while preserving sightlines

- Steel palisade: High physical resistance and visual deterrence for critical sites

Materials behave differently in Canadian conditions; the next subsection gives a compact comparison to support procurement decisions.

Benefits and common uses of industrial security fencing

Industrial security fencing focuses on deterrence, durability, and customization to meet operational and regulatory needs across warehousing, utilities, manufacturing, and institutional campuses. Benefits include longer service life with galvanization or protective coatings, modular integration for gates and access control, and the ability to tier security features to match assessed risks. For example, a plant may choose welded mesh with anti-climb topping to protect production while keeping visibility, whereas a water treatment facility might favor palisade and controlled access. That distinction is why industrial fencing differs from commercial fencing and informs specifications.

Material selection is the next step. The table below compares core attributes to guide that decision.

| Material/Type | Durability | Security level | Cost | Maintenance / climate suitability |

|---|---|---|---|---|

| Galvanized chain link | Moderate | Low–medium | Low | Low maintenance overall; vulnerable at cut points unless coated or vinyl-covered |

| Welded wire mesh (coated) | High | Medium–high | Medium | Performs well in freeze-thaw and salt exposure when properly coated |

| Steel palisade | Very high | High | High | Durable against impacts and climbing; coatings recommended near salt exposure |

| Vinyl-coated / ornamental steel | Medium–high | Medium | Medium–high | Aesthetic option with moderate upkeep; coatings help resist corrosion |

| Temporary panel fencing | Low | Low | Low (rental) | Fast to deploy; not intended for prolonged exposure |

How gates and access control upgrade perimeter security

Gates and access control turn a passive fence into an actively managed boundary by regulating throughput, creating audit trails, and integrating with surveillance. Gate types—sliding, swing, cantilever, and bi-fold—must be specified for cycle rate and durability to match operations. Automated operators, backup power and sensors keep gates working during outages. Access hardware—keypads, card readers, intercoms and remote platforms—adds layered authentication and entry logs that improve both security and logistics. When gates and fence materials are engineered together, the perimeter deters, detects, denies and documents access events.

Effective integration means choosing gates that match throughput and environmental stressors. Typical industrial gate types include:

- Sliding gates: Best for long spans and heavy-duty daily use where lateral space is available

- Cantilever gates: Ideal where ground tracks are impractical or debris could block a sliding mechanism

- Swing gates: Simple solution for low-frequency access points with clear swing space

- Bi-fold gates: Compact footprint for tight entries that need quick cycles

Gate selection informs automation and access-control specs. The table below compares common automated gate systems.

Automated industrial gate systems — practical comparison

The table compares operation, throughput and integration notes so managers can match gate choice to daily cycles and security needs.

| Gate type | Operation | Typical throughput | Integration / notes |

|---|---|---|---|

| Sliding (motorized) | Lateral movement on track | High | Good for heavy use; requires a clear track and regular maintenance |

| Cantilever (motorized) | Overhung, counterbalanced | High | No ground track; better where debris or frost is a concern |

| Swing (operator-assisted) | Pivoting panels | Low–medium | Simpler mechanics; limited by swing clearance and wind |

| Bi-fold (folding) | Panels fold to save space | Medium | Compact footprint; mechanics are more complex |

How access control improves fence security

Access control enforces authentication, records entries and ties into supervisory systems to handle exceptions and emergencies. Options range from keypad controllers to card readers and biometric stations; each adds operational control and auditability for deliveries, shift changes and contractors. Integration with CCTV and intrusion detection enables event-driven recordings and faster responses, while remote management tools allow administrators to update credentials and schedules without site visits. For high-throughput sites, prioritise speed, reliability and redundancy in access hardware to reduce bottlenecks while keeping security strong.

Compatible access hardware depends on gate mechanics and workflows; the next section covers temporary fencing where rapid deployment changes access-control planning.

When temporary industrial fencing is the right choice

Temporary industrial fencing is a modular, rentable solution for construction zones, events, remediation, and emergency containment—situations that need fast deployment and reusability. These systems provide site containment, controlled traffic, and flexible layouts that adapt as project footprints change. Panels commonly use concrete or weighted bases, wind bracing and privacy screening to meet safety and public-protection needs. Renting reduces upfront capital for short-term projects. Knowing when to use temporary fencing prevents over-specifying permanent systems for transient requirements.

Key advantages of temporary fencing include speed, flexibility and cost control; core benefits are:

- Rapid deployment: Panels can be delivered and erected quickly for urgent containment

- Modularity: Layouts reconfigure as site conditions change during a project

- Lower upfront cost: Rental models reduce capital expenditure for short-term needs

Those strengths make temporary fencing a common choice for construction, events and emergency response. The next subsection outlines the specific advantages in more detail.

Advantages of temporary industrial fencing

Temporary fencing provides safety and security without long-term commitment: quick setup, reusable panels and straightforward removal when the work finishes. Beyond cost savings, temporary systems accept accessories—privacy slats, signage and access gates—to meet safety messaging and crowd-control needs. Where pedestrian interaction is high, add supervised access points or anti-climb features for extra protection without a permanent install. Standardised panels simplify logistics and reduce administrative overhead for short-term projects.

Choosing temporary panels also affects contract planning for delivery, installation and return logistics; the next subsection covers industries that rely on modular perimeter solutions.

Industries that commonly use temporary fencing

Temporary fencing is widely used in construction, utilities, events, remediation and emergency services because each needs controlled access and public protection for finite periods. Construction sites separate work zones from the public and secure equipment; utilities use panels during maintenance or outages to protect crews; event organisers use modular fences for crowd control and ticketing perimeters. Emergency responders and remediation teams depend on rapid containment to secure hazardous areas while assessments proceed. These use cases show temporary fencing’s versatility for managing risk during temporary operations.

Understanding these deployment patterns helps inform permanent fencing choices later in a project lifecycle. The next section explains the installation and maintenance process for industrial fences.

Industrial fence installation and maintenance — the process

A dependable fence project follows a consultative sequence: consultation, site survey and design, permitting and specification, installation, inspection, and ongoing maintenance. Each step delivers a clear outcome and reduces surprises in procurement. The process aligns stakeholders, clarifies site constraints, and ensures materials and gates meet operational needs and codes. Clear timelines and client input at each phase speed quoting and reduce change orders. The table below summarizes common service steps, deliverables, and client responsibilities so expectations are clear before engaging a contractor.

| Service step | Deliverable / timeframe | Client input / typical issues |

|---|---|---|

| Consultation & site assessment | Scope summary within days | Site access, rough measurements and use-case notes |

| Design & specification | Drawings and materials list (1–2 weeks) | Approve materials, heights and gate locations |

| Permitting & approvals | Permit-ready documents (timing varies) | Local permit rules and site constraints |

| Installation | Fence built to spec (days–weeks) | Site access, staging area and utility locates |

| Inspection & handover | Final inspection report | Walk-through and punch-list items |

| Maintenance program | Scheduled inspections (annual/seasonal) | Access for routine checks and repairs |

How Fencer 3000 tailors industrial fencing solutions

We take a consultative approach to match materials, gate systems and access control to each site’s security needs and workflows. Fencer 3000 provides free consultations and custom quotes to simplify decisions. During the site review we map access points, traffic flows and environmental exposure to recommend appropriate materials—for example, coated welded mesh for salt-exposed areas or palisade where maximum resistance is required. Custom work includes bespoke gate fabrication and integration planning for automation and readers so gates and fences operate as a single system. That site-specific focus reduces specification errors and speeds the move from concept to installation.

Best practices for industrial fence repair and maintenance

Routine inspections, seasonal maintenance and prompt repairs extend fence life and keep security effective. Inspect anchors and coatings annually, remove vegetation that blocks sightlines, and repair cut or bent panels quickly to prevent escalation. Check corrosion protection—galvanization or polymer coatings—during inspections and prioritise fast, local repairs (weld patches, post replacements) to restore function. In Ontario, address freeze-thaw stresses and salt exposure with proper coatings and attention to footings; schedule checks after winter thaw and major storms. A maintenance contract with defined response times gives predictable lifecycle costs and accountability.

Proactive upkeep reduces emergency repairs and supports warranty conditions. The following section explains why a local Mississauga specialist simplifies acquisition and lifecycle management.

Why choose Fencer 3000 Inc. for industrial fencing in Mississauga and Ontario?

Fencer 3000 is a Mississauga-based fencing and access-control company serving the Greater Toronto Area. We focus on durable, low-maintenance systems and site-specific solutions. Our value proposition includes free consultations and custom quotes that align materials and gates to Ontario climate challenges and your operational needs. As a local provider, we coordinate site surveys and installations across nearby municipalities, reducing logistics friction and speeding project timelines. For decision-makers who need practical specifications and a single point of contact for fences, gates and access control, working with a local specialist brings procurement, installation and maintenance together.

- Local presence: Faster site visits and local climate knowledge produce accurate proposals

- Tailored specifications: Solutions matched to site risk and operational throughput

- Integrated services: Fencing, gates, and access control coordinated under one contract

Those differences speed quoting and cut coordination overhead. The next subsection highlights material and installation practices that deliver durability and low maintenance.

What makes Fencer 3000’s industrial fencing durable and low-maintenance?

Durability starts with the right materials and protective finishes plus correct foundation design and installation. We favour coated or galvanized steel panels and correctly sized concrete footings to limit corrosion and movement from freeze-thaw cycles. Using anti-climb mesh or palisade where needed meets security goals without over-specifying. Proper installation—accurate post alignment, concrete embedment and quality fasteners—reduces long-term maintenance. Those material and installation standards create systems that stay secure and serviceable in Ontario’s variable climate.

Good installation leads to predictable inspection and maintenance cycles. The next subsection describes our consultative quoting approach.

How Fencer 3000 supports clients with free consultations and custom quotes

Our workflow starts with a free consultation and site review, then a tailored proposal that lists materials, gate and access-control specs, and maintenance recommendations. Clients are asked for site details—address, approximate fence length, photos or plans, desired security level and timeline—to speed accurate quoting. We schedule a site visit for final measurements when required. Proposal turnaround depends on complexity, but our structured intake reduces back-and-forth so stakeholders can compare options side-by-side. For local projects we coordinate surveys and installations across the GTA to streamline logistics and delivery.

Common questions about industrial fencing

Procurement and facilities teams often ask which fence types are most secure, which materials are best suited to Canadian climates, and which permits are required. Short, direct answers help teams finalize specifications faster. The Q&As below give clear responses and next steps—site survey, permit check, and integration planning—to keep projects moving.

Q. What is the most secure type of industrial perimeter fence?

The most secure systems pair strong materials, anti-climb geometry and topping measures. Steel palisade and anti-climb welded mesh offer top physical resistance and delay. Palisade resists cutting and scaling; high-grade welded mesh with narrow apertures resists cutting and footholds. Both perform best with robust footings and tamper-resistant fixings. Where allowed, barbed or razor-style topping increases resistance, and tying fences into intrusion detection and CCTV turns physical delay into actionable security. Choose the right level based on a threat analysis and operational needs, balancing cost against required protection.

Those principles guide material recommendations for Ontario, discussed next.

Q. Which materials are best for industrial fencing in Canadian climates?

Materials for Canadian climates prioritise corrosion resistance and resilience against freeze-thaw cycles. Galvanized and polymer-coated steel are leading choices for long service life. Coated welded mesh handles salt exposure and freeze-thaw stresses better than uncoated chain link, while palisade with proper coatings resists impact and scaling with minimal upkeep. Schedule inspections after winter and ensure good drainage around footings to prevent standing water and frost heave. Choosing coated steel and specifying correct installation and drainage delivers the best lifecycle value in Ontario weather.

Q. How to request a free consultation for your industrial fencing project

Requesting a free consultation starts with preparing basic site information so a provider can produce an accurate, customized quote without repeated clarification. Typical intake items are site address, intended use and security goals, approximate linear footage, photos or plans, preferred materials or constraints, and an estimated timeline or budget. Providing these up front shortens the consultative loop and enables quicker site visits and proposals. To contact a local Mississauga specialist, call the company or find its Google Business Profile to arrange a consultation and read local reviews.

Use this checklist to prepare before requesting a quote:

- Site address & photos: Clear images of the perimeter and access points

- Approximate length & layout: Rough measurements or plans

- Use & security requirements: Expected access patterns, vehicle types, and risk level

- Timeline & budget: Desired start date and a budget range

Having these items ready enables a smoother assessment and faster, more accurate proposals.

Q. What information do you need for a customized quote?

For a customized quote, provide the site address, photos or sketches of the proposed fence line, intended use (storage yard, loading area, etc.), approximate linear footage, expected gate locations, and any special requirements such as vehicle access, CCTV integration or temporary fencing phases. These details let estimators prepare accurate material lists, gate specs and timelines and reduce follow-up questions. Mention seasonal constraints—preferred installation windows—to help schedule work. Gathering this information beforehand speeds the free consultation and quotation process.

When you’re ready, use the contact channel below to start a consultation with a local provider.

Conclusion

Choosing the rightindustrial fencing in Mississauga improves security, compliance, and operational efficiency. By understanding materials, fence types, and security features, you can make informed decisions that protect assets and simplify access control. Partnering with a local expert like Fencer 3000 gives you tailored support and timely service through every project phase. Contact us to discuss how we can secure your industrial site effectively.

Frequently Asked Questions about Industrial Fencing

Q. What factors should I consider when choosing industrial fencing for my site?

Consider the security level you need, the materials that stand up to local weather, and your site’s operational needs. Assess risks like theft or unauthorised access and pick a fence type that meets those risks. Also factor in maintenance, installation timelines and permit requirements. A local expert can help tailor the solution to your site and budget.

Q. How can I ensure my industrial fence complies with local regulations?

Start by checking zoning and building codes with your municipality or consult a fencing contractor familiar with local rules. Key items include height limits, material restrictions and permits. Working with a professional who knows local regulations simplifies the process and reduces the risk of delays or rework.

Q. What maintenance is required for industrial fencing?

Maintenance typically means regular inspections for damage, corrosion or wear. Depending on the material, apply protective coatings or make repairs as needed. Galvanized steel generally needs less frequent attention than untreated materials. Keep vegetation cleared to preserve sightlines and structural integrity. A routine maintenance schedule prevents bigger problems and extends fence life.

Q. Can temporary fencing be used for long-term projects?

Temporary fencing is designed for short-term use but can be adapted for longer projects in some cases. Assess durability and security needs—if the project runs long, consider switching to a permanent solution for better protection and regulatory compliance. Temporary fencing remains a flexible, cost-effective option for evolving project needs but may not match the security of a permanent install.

Q. What are the costs associated with industrial fencing installation?

Costs vary based on material type, fence length, and site complexity. Additional expenses can include permits, site prep, and access-control systems. To get an accurate estimate, consult a fencing contractor who can assess your site and provide a detailed quote covering all likely costs.

Q. How do I choose the right access control system for my industrial fence?

Evaluate your site’s security needs, traffic patterns and workflows. Consider keypads, card readers or biometric systems depending on the required security level. Make sure the access control integrates with your gates and fence hardware. Consulting a security professional helps you balance security, convenience and cost while meeting any applicable regulations.